Leading the Way in Advanced Manufacturing

we are at the forefront of electronic manufacturing services, equipped with cutting-edge facilities designed to ensure unparalleled quality and efficiency.

Redefining Electronic Manufacturing Excellence

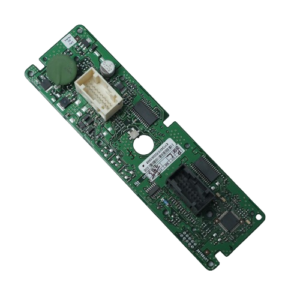

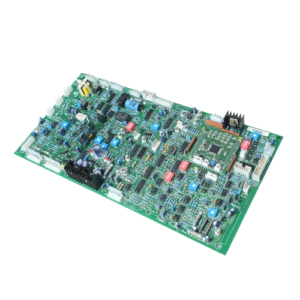

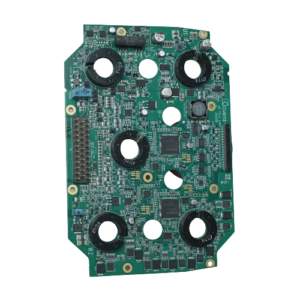

Precision-Built PCBA Solutions with End-to-End Manufacturing Capabilities

Our Electronic Manufacturing Services (EMS) Division is dedicated to producing high-performance Printed Circuit Board Assemblies (PCBA) for automotive, industrial, and power electronics sectors.we deliver quality, scalability, and innovation tailored to the evolving needs of OEMs.

We have our dedicated automation team to make jig, fixture, end of line testing with auto flash programming

CONCEPT DESIGNING

Custom solutions for specific markets

Client collaboration for optimal design

Performance-focused layouts

Schematic to Gerber conversion

Early risk analysis (DFMEA)

PROTOTYPE DEVELOPMENT

Rapid prototyping capabilities

EMI/EMC compliance testing

DFMEA & PFMEA integration

Quick iterations for refinement

Hardware & software coordination

MASS PRODUCTION OF PCBA

5 advanced SMT lines

ROHS-compliant processes

Full ESD protection

Auto-insertion machinery

In-line AOI & ICT testing

VALIDATION

Burn-in testing

Vibration testing

Humidity testing

Functional & dynamic checks

Pre-dispatch performance validation

In-House Testing Solutions

We offer comprehensive testing capabilities, including ICT Test Jigs, Burn-In Testing, and Functional Testing (embedding with hardware, software and GUI ) to ensure the highest quality control at each step. Our Precision in Gerber File Development, along with automated optical inspection (3D-AOI) and 3D-SPI, ensures that all products meet stringent quality checks. With our In-Circuit Tester (ICT) and manual insertion lines, we ensure the reliability and functionality of each product before it reaches the market

Automotive Manufacturing

Defence Industry

Industrial Manufacturing

Railway Industry

Consumer Requirement

Box Build Assemblies

KCL provides systems integration that is basically a complete assembly of your electronics placed in an enclosure. Since the box build process can vary as much as design calls for, we work closely with the customers and giving hand hold in reverse engineering, supplier development, process qualification and drop ship abilities.

Powering Progress with Advanced EMS Solutions

At KCL, we are at the forefront of Electronic Manufacturing Services (EMS), equipped withcutting-edge facilities that ensure unparalleled quality, precision, and efficiency. Ourcomprehensive services cover the entire lifecycle of electronic products, from concept design to massproduction, with a focus on innovation and reliability. We take a collaborative approach withclients, delivering tailored solutions that meet market demands and exceed expectations